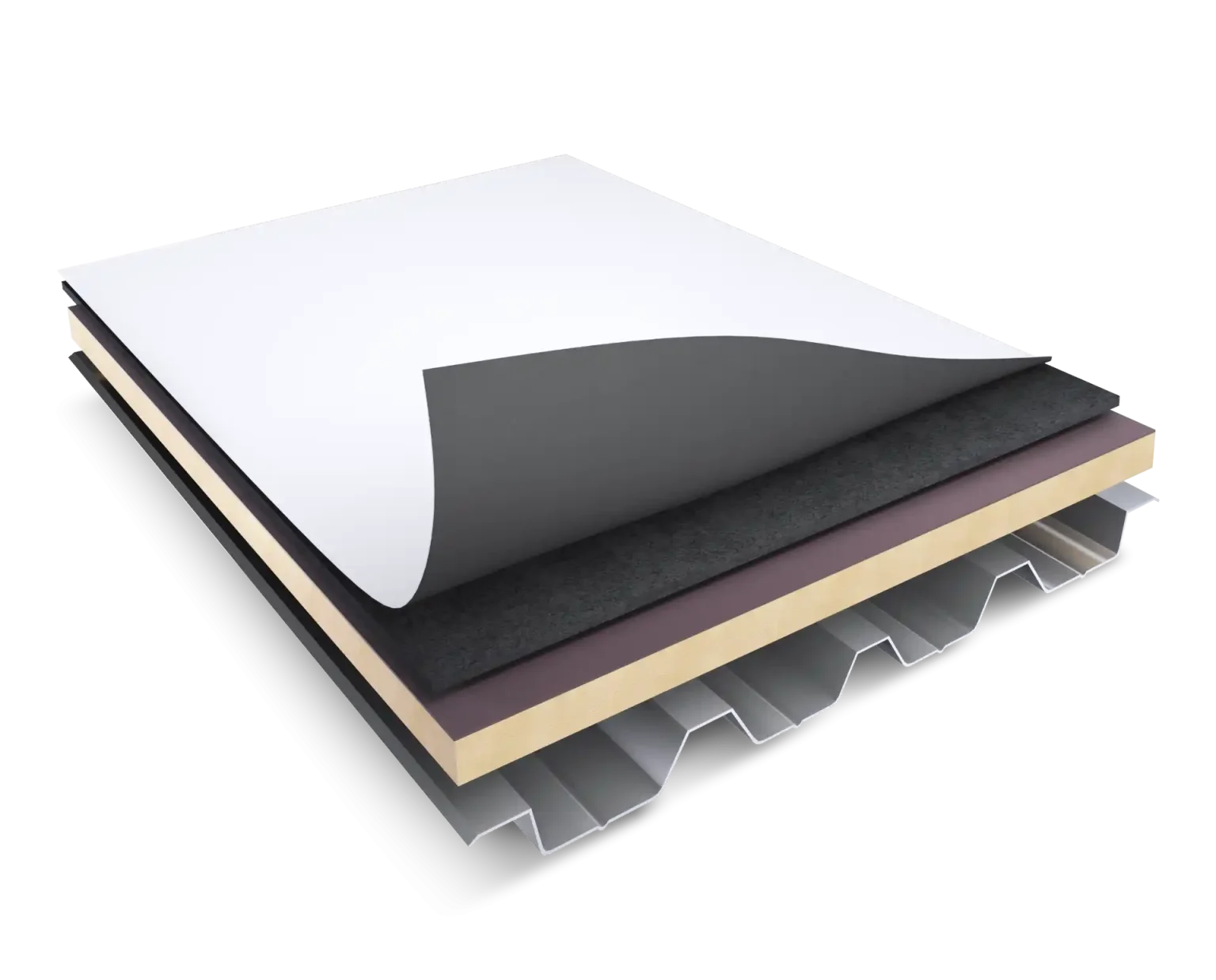

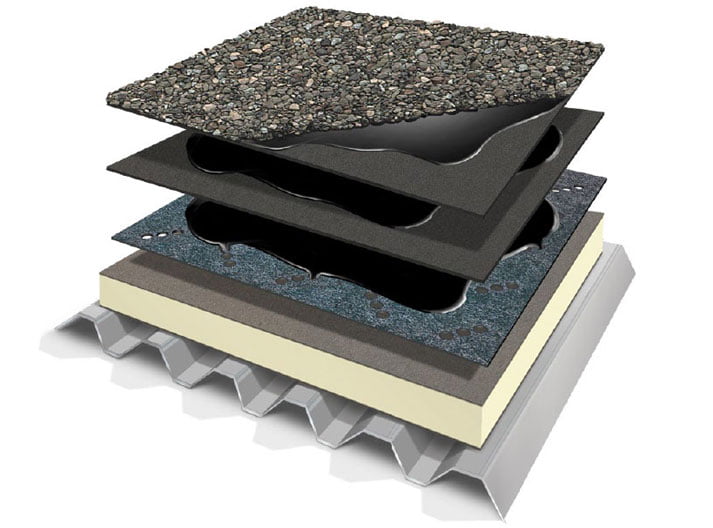

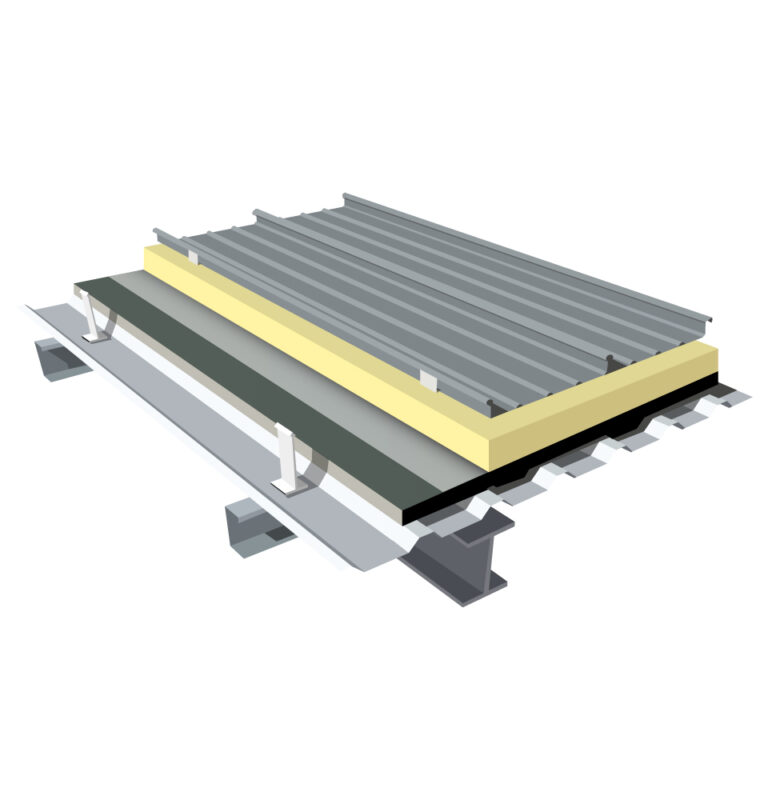

Reliable code-compliant installs • Long-term warranties

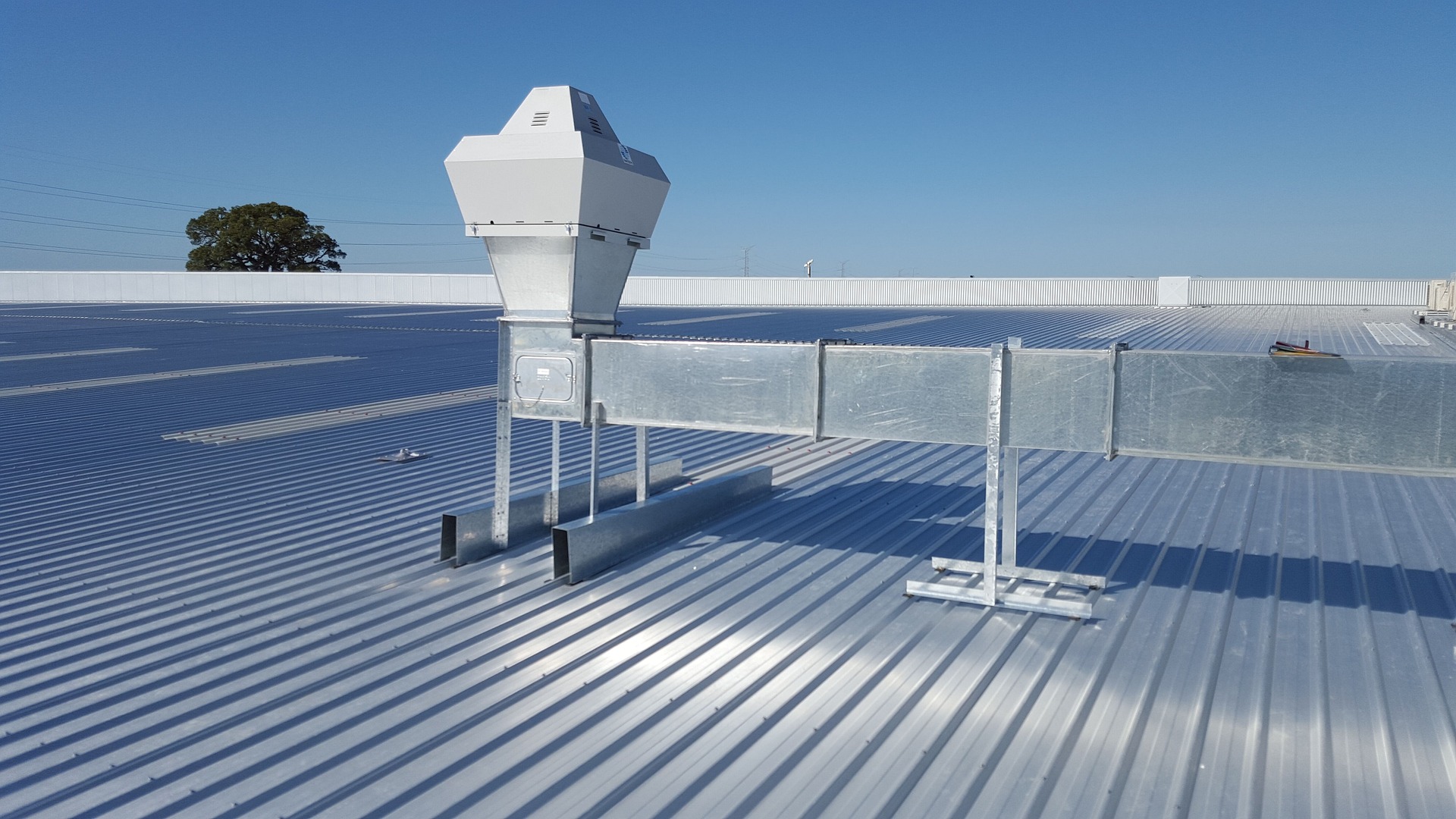

Commercial Roof Installation in Austin, TX

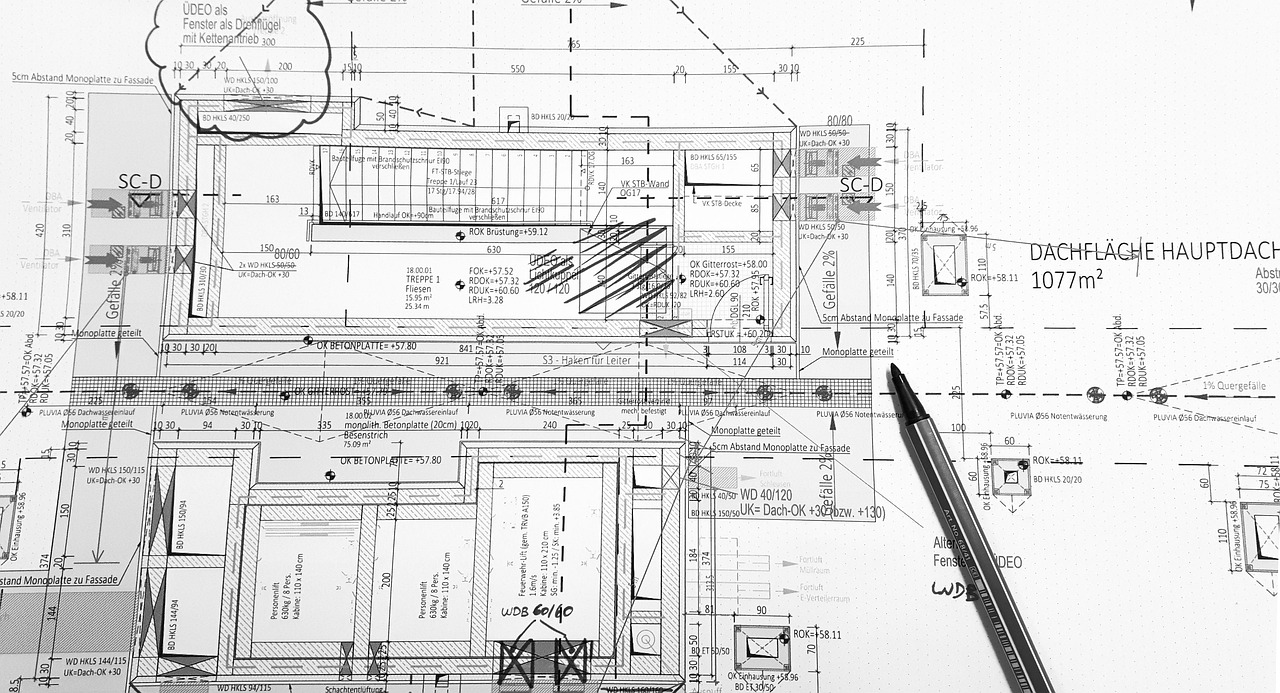

New commercial roof systems engineered for Texas heat, hail, wind, and code requirements—installed by certified professionals who deliver on schedule and on budget.